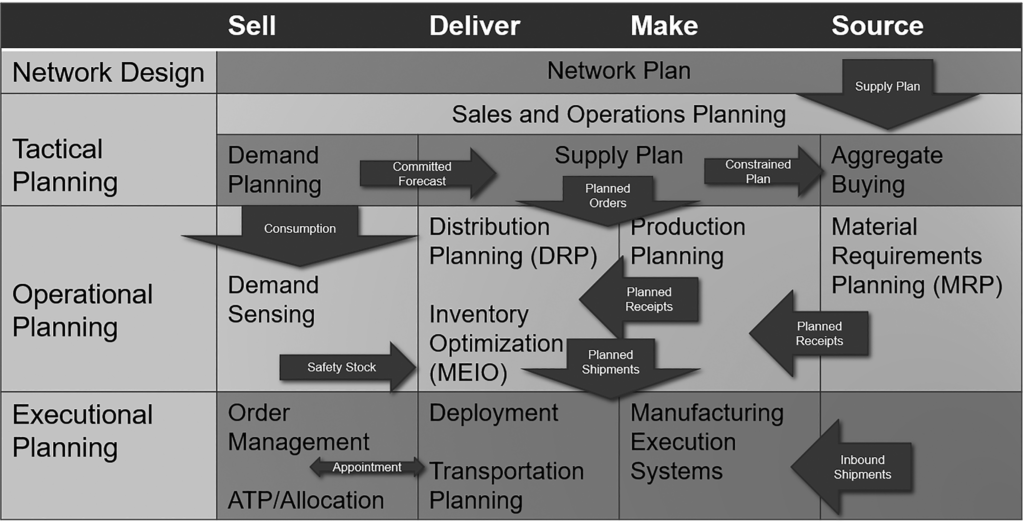

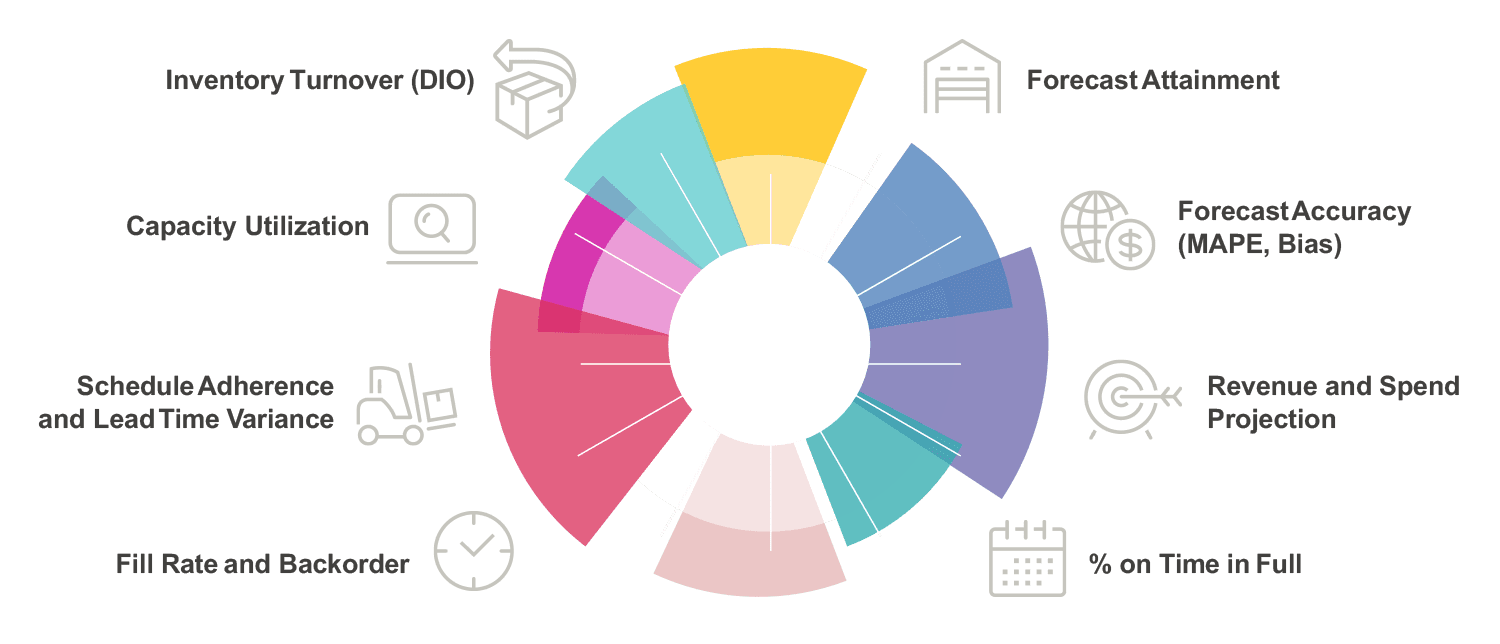

The Arkieva tool creates a link between people, process, tools and analytics by providing easytouse, configurable, collaborative planning solutions that encourage a more synergized planning process A common struggle for any endtoend process management is identifying the right measures that encapsulate the value of the process This interactive article contains key performance indicators (KPIs) that allow organizations to focus all participants in the endtoend sales and operations planning (S&OP) process on a shared goal that aligns with the strategic purpose of the process The missing element is a coherent model that supports the tactical and financial plan, but is also capable of supporting S&OP with detailed mapping to supply chain execution It is a modeling environment of the entire process that is coherent from top

From Chaos To Control July 1 08 Cscmp S Supply Chain Quarterly

Sop process mapping

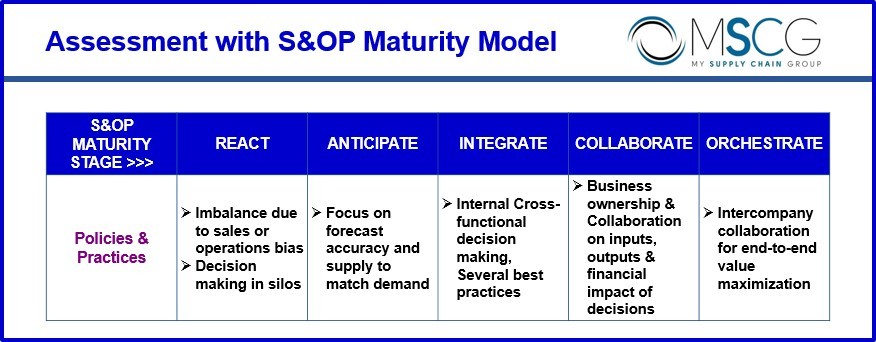

Sop process mapping- Sales and Operations Planning (S&OP) Sales and operations planning (S&OP) is a business management process where leadership and executive teams meet to ensure each business function is aligned to balance supply and demand S&OP requires crossorganizational collaboration to create detailed forecasts for predicted salesThe maturity of 5 Steps S&OP Process on Scale of 15 (1 Lowest & 5 Highest) S&OP Advance Stage Questions;

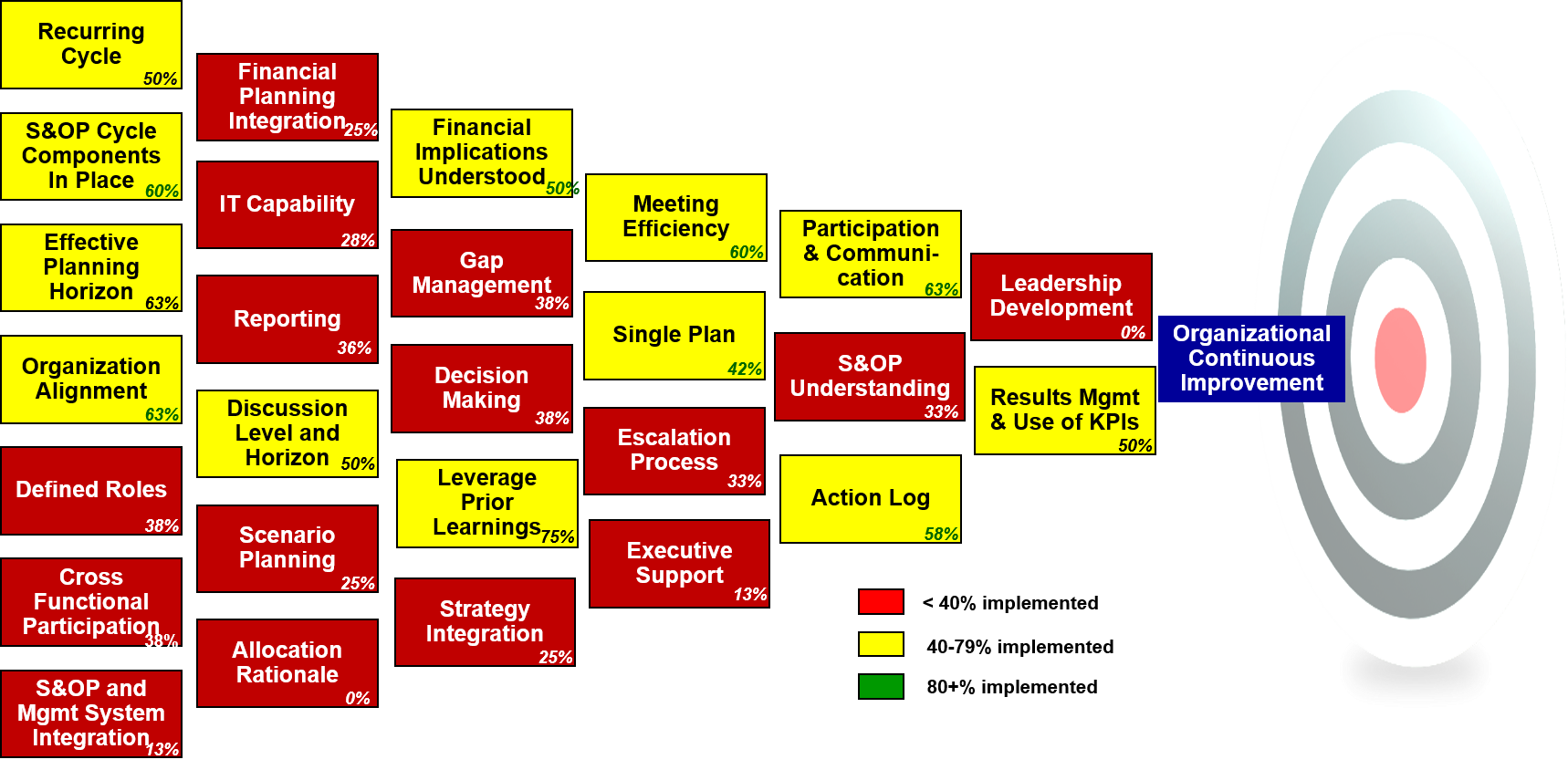

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

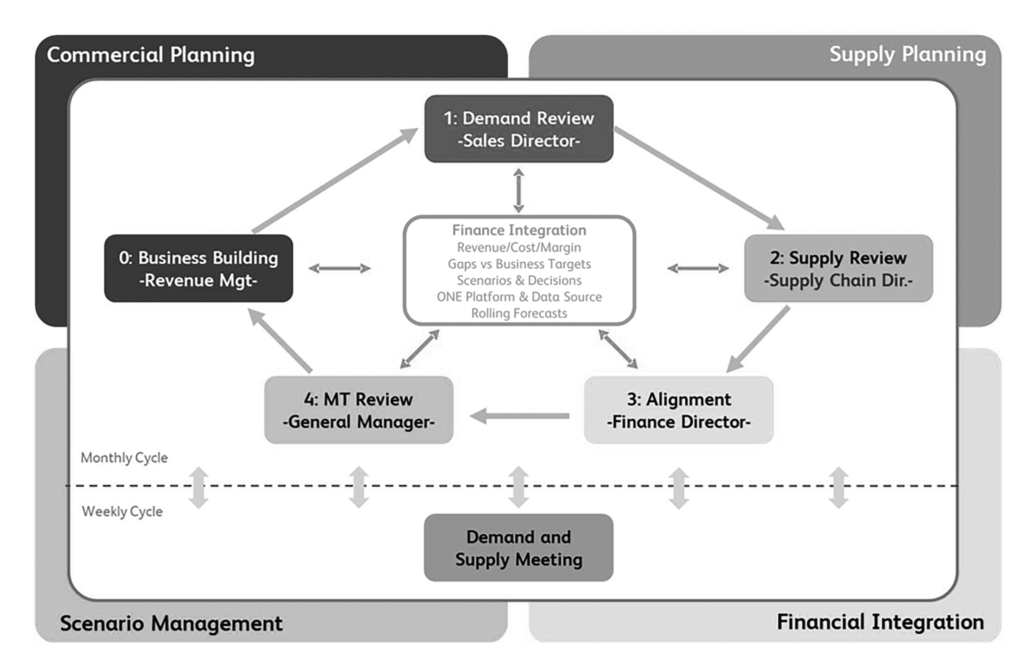

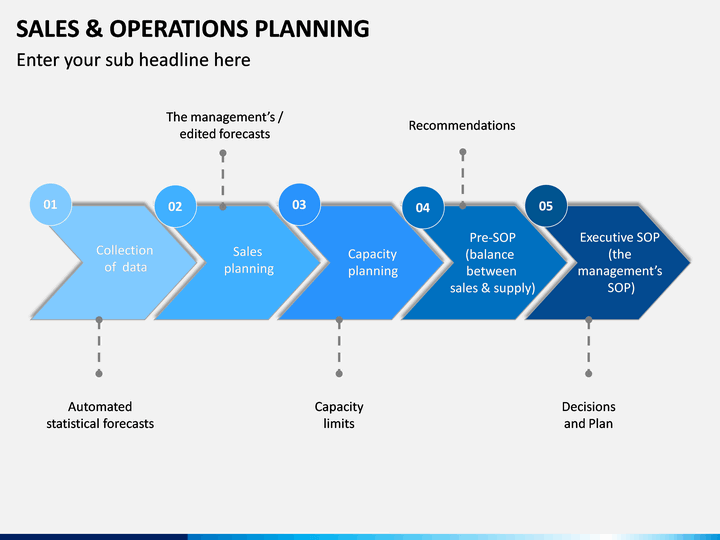

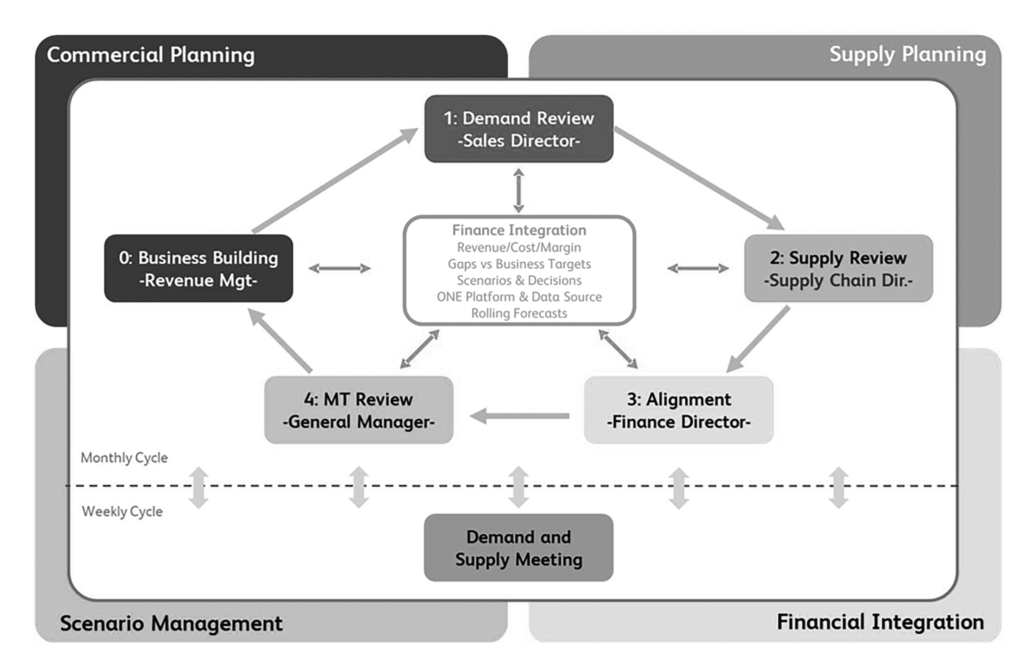

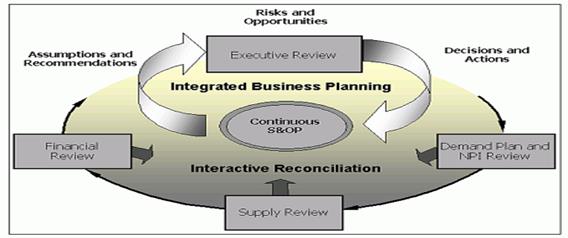

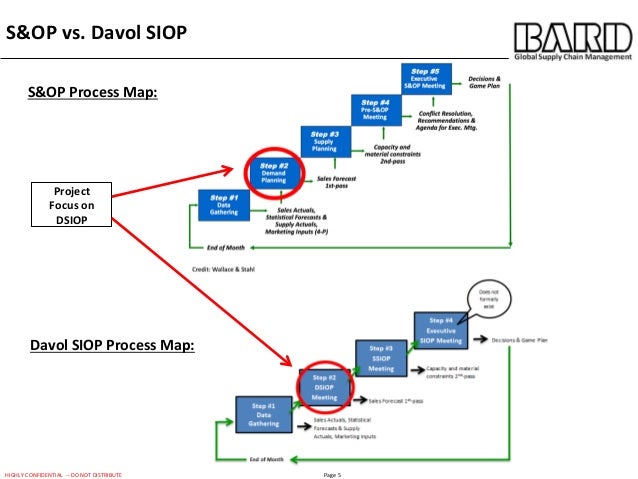

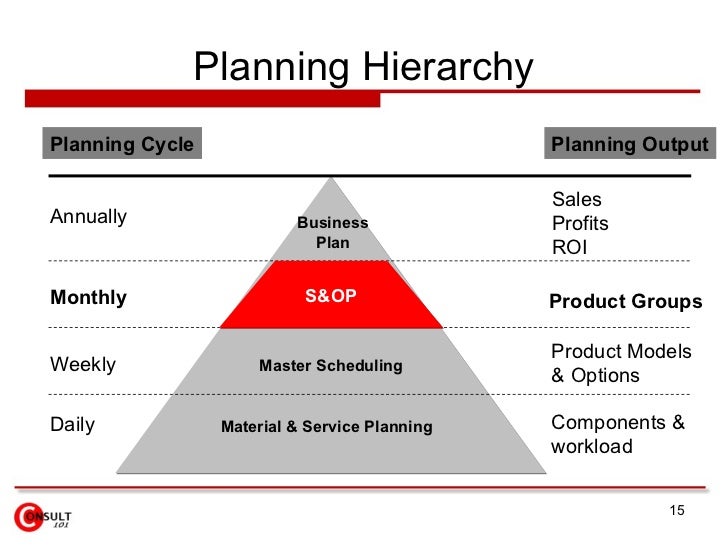

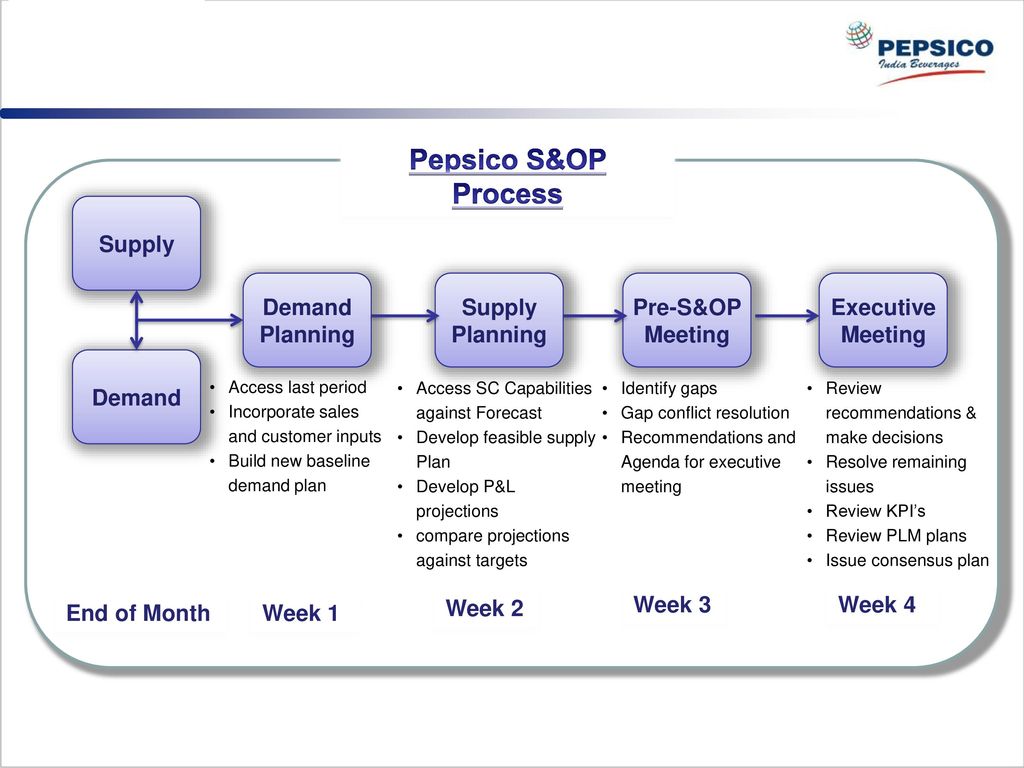

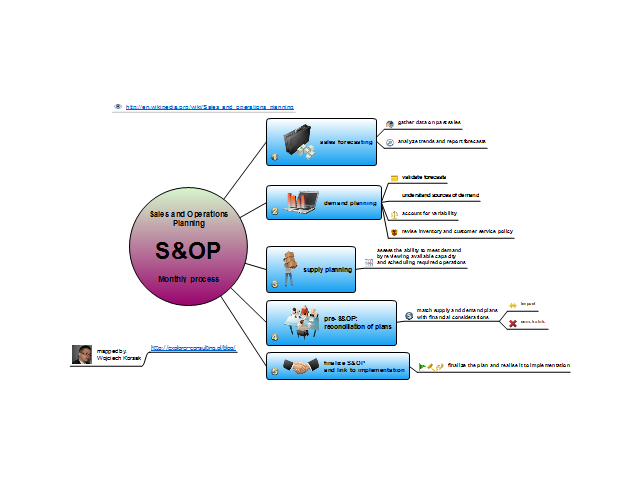

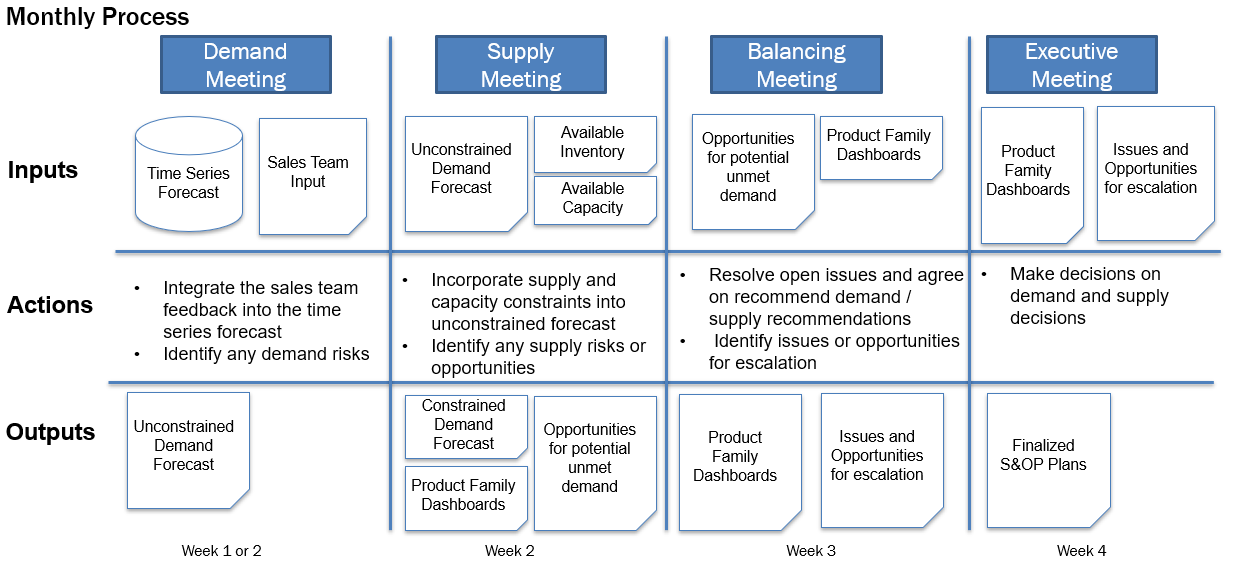

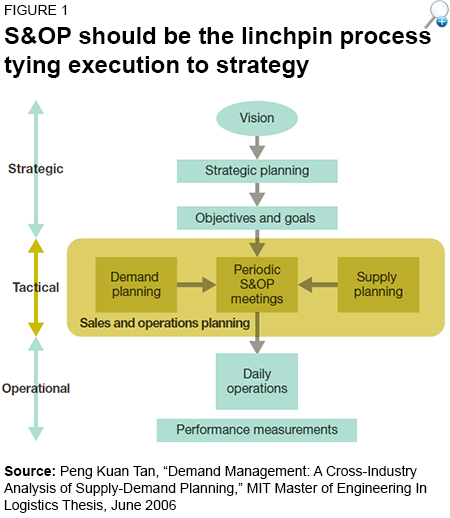

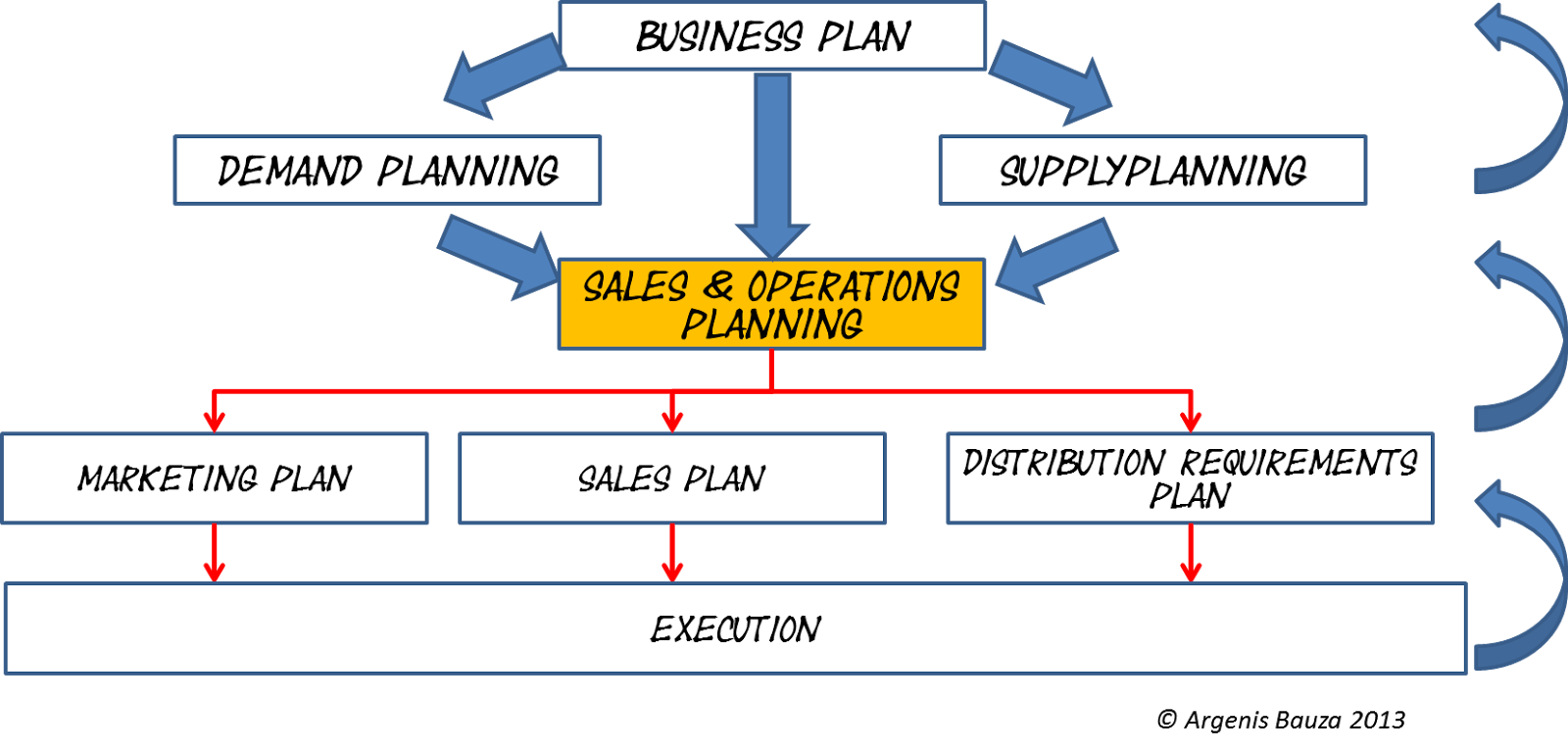

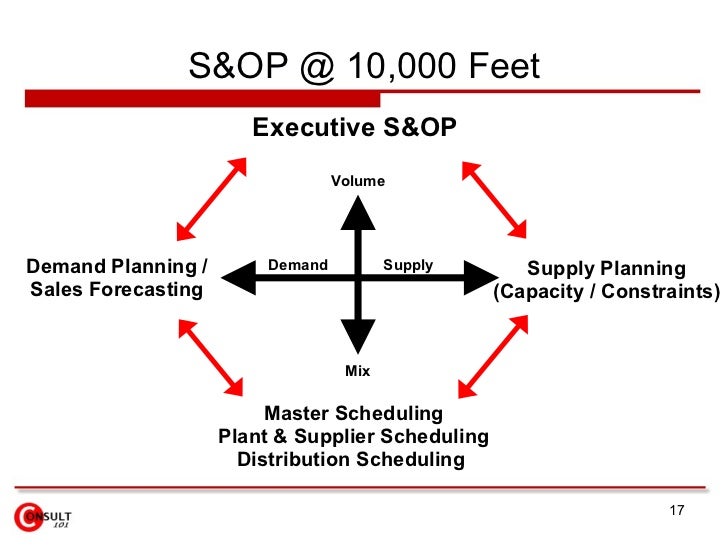

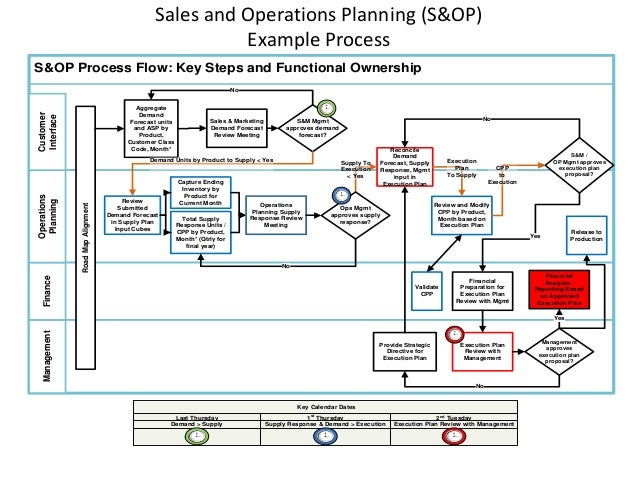

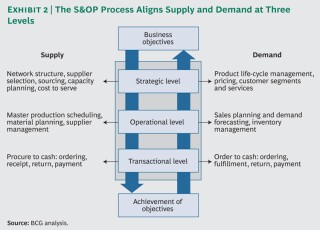

S&OP deals with the continuous change that occurs in the business and is a process to effectively manage ongoing change In practice, it is called a replanning process S&OP is owned by the GM or CEO It is a crossfunctional process and includes all the functions of the company Correctly implemented, it is a demand and strategydriven process S&OP gives management the ability to direct its business to achieve a sustainable competitive advantage The overall objective of S&OP is to arrive at a business "Game Plan" to help manage and allocate critical resources to meet the needs of the customer at the lowest cost S&OP is a fivestep process as illustrated in Figure 1 S&OP is a structured monthly process that aligns all functional areas under a unified set of assumptions to enable and coordinate decision making It integrates demand, supply, operations, and financial planning into one game plan for business

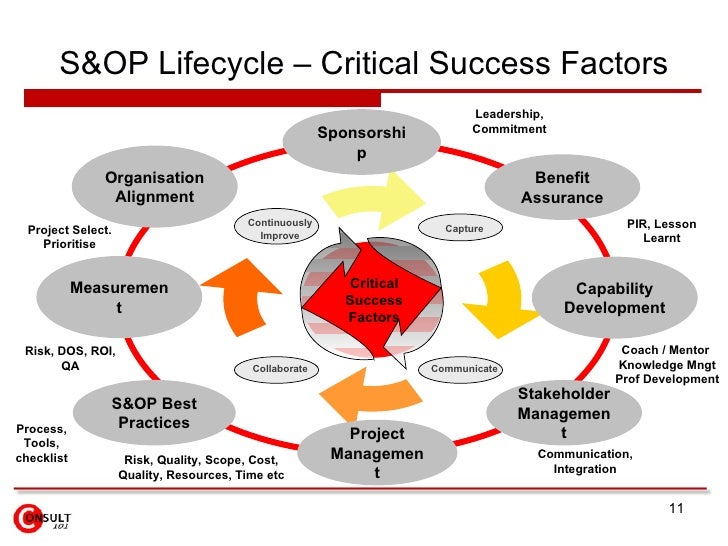

The segmentlevel S&OP process is the most important tactical planning process inside any business The purpose is to implement the business strategy in each market segment The gotomarket strategy comes to real life inside the S&OP process Each functional area has a specific role and is engaged in the overview of the whole business The 'Why' in S&OP or How to Find More Meaning There is a lot of evidence that S&OP is hard to implement and get right And when S&OP is implemented it often stalls, doesn't make enough progress and doesn't deliver enough value The reasons are plenty, but one of the core reasons is the lack of senior leadership supportInformative video describing the S&OP Process as it relates to SAP IBP Krypt, Inc is your consulting partner for implementing SAP IBP

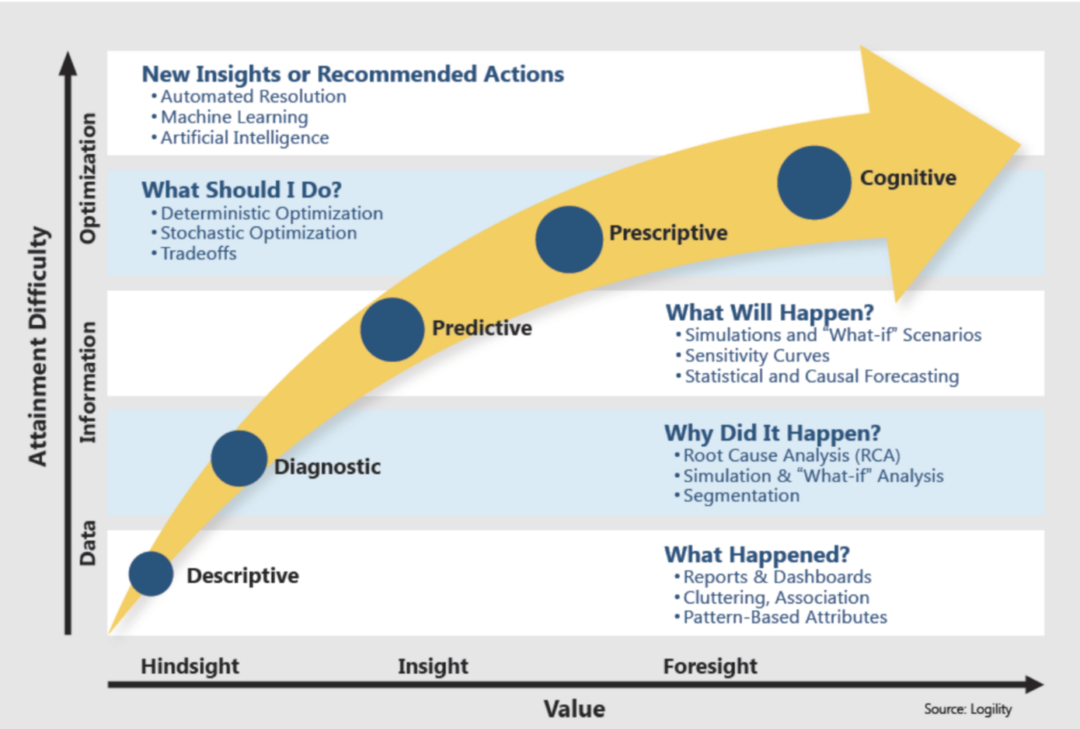

Although a good S&OP process is an excellent way to improve of the flow of information between various parts of a business, the primary benefit of the S&OP process is the actionrelated decisions that stem from it If the S&OP process does not directly result in improved decision making then, to put it bluntly, you're wasting your time By Karin Bursa The biggest obstacles to S&OP excellence stem from the complexity of managing the process which requires amongst other things, identifying, gathering and analysing relevant data, effectively managing participants and information Here Karin Bursa of Logility outlines a fivestep road map to organising the tasks and analyses needed to S&OP excellenceIts purpose is to aid you in understanding the planning balance between

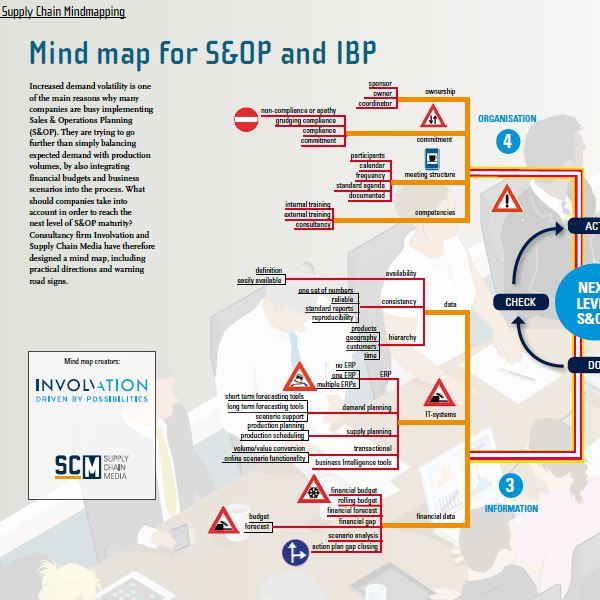

Mindmap For S Op And Ibp Supply Chain Movement

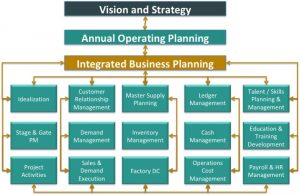

A Comprehensive Overview Of Sales And Operations Planning S Op

Organisations with effective S&OP processes are more committed 77% of survey participants with self proclaimed effective S&OP processes answered yes to the question 'S&OP stakeholders are timewise committed to this process, planning rules and agreed priorities' Versus 44% for ineffective S&OPS&OP stands for sales and operation plan and sales and operations planning at the same time It is both a plan and the process that creates, implements, monitors, and continuously improves the plan The S&OP process involves a series of meetings to meet a consensus A demand and production plans that reflect the results of demandside sensingSteps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are

Sales Operations Planning Omnics

Supply Chain Process Map How To Start Building It

S&OP is gaining attention among organizations eager to implement powerful tactical management processes to help them succeed while navigating a rapidly changing business landscape Short for Sales and Operations Planning, S&OP is an integrated business management process that aligns all facets of an organization to their key market goals, synchronizing them and allowing theAnd the second is grounded in collaborativeAccording to IBF, S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply When establishing your process, it is important to consider who will be responsible for each step of the process You will also want to set expectations for handoffs, meetings, and how you will

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Sales And Operations Planning Powerpoint Template Sketchbubble

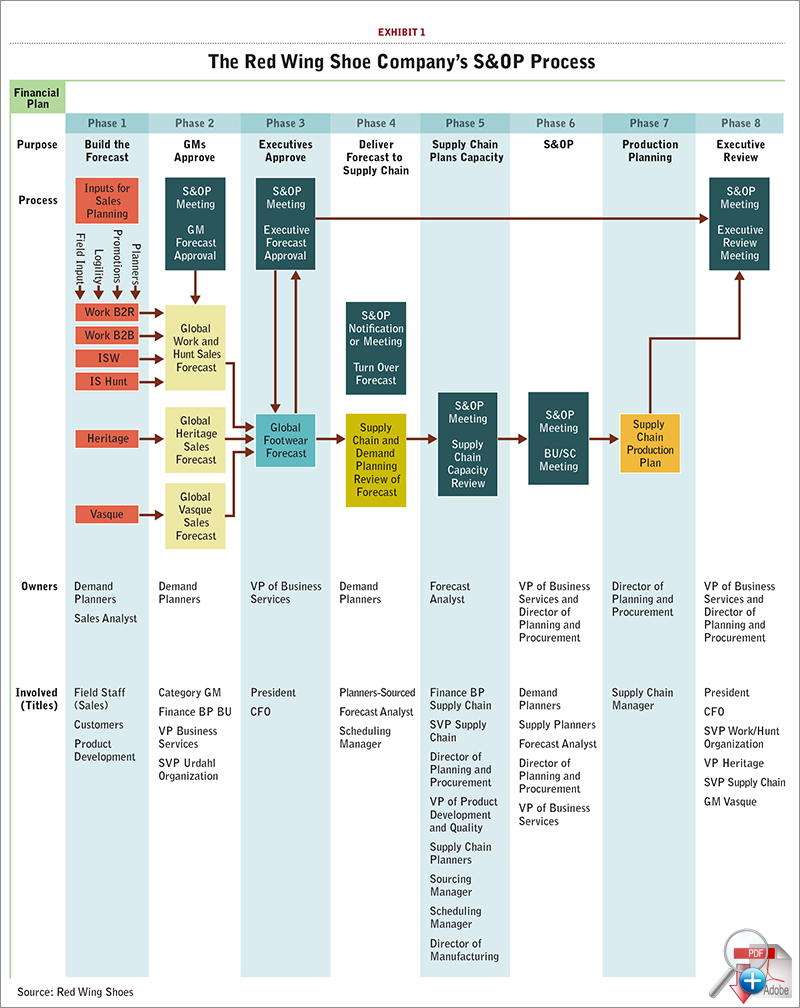

The process requires outlining data collection processes, timing and responsibilities of the participants Start by prototyping the key concepts and establishing detailed processes for demand, supply and consensus building Define the data requirements (population) and develop the SI&OP tools, report formats, key measures and meeting packagesA process map is a planning and management tool that visually describes the flow of work Using process mapping software, process maps show a series of events that produce an end resultA process map is also called a flowchart, process flowchart, process chart, functional process chart, functional flowchart, process model, workflow diagram, business flow diagram or process Monitoring the S&OP comes down to monitoring the assumptions Download Whitepaper 8 essentials of an S&OP Software Key Steps for Monitoring S&OP Performance The first step is to identify the key assumptions If the S&OP process includes promotions as in the CPG industry, promotion success may be critical

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

2

Find local businesses, view maps and get driving directions in Google MapsSimplistically speaking, the S&OP process does exactly what it says on the tin – it provides a general overview of company's Sales and Operations Planning method! Explore the program Classical SAP Road Maps Explore road maps that can enhance business capabilities and access the road maps that are in the process of being migrated to the SAP Road Map Explorer tool Access the road maps Roadmap Viewer SAP Activate provides a clear, structured, and guided process that expedites deployment of SAP solutions

The Lost Link To Make Strategy Work Sales Operations Planning S Op Strategok By Javier Go Sales And Operations Planning Business Architecture Strategies

Sales And Operations Planning Basics Tutorial

theoretical s&op dashboard model in practice Curious to see how the Arkieva S&OP software supports these functionalities?Seven S&OP Reports Every Manufacturing Executive Needs 7 2 S&OP Executive Review Dashboard This dashboard facilitates the S&OP executive review process The consensus or preS&OP meeting provides the details to the executive review process, and this dashboard provides visibility into the status of those submitted operations and supply chain plansWhat Is Sales and Operations Planning (S&OP)?

From Chaos To Control July 1 08 Cscmp S Supply Chain Quarterly

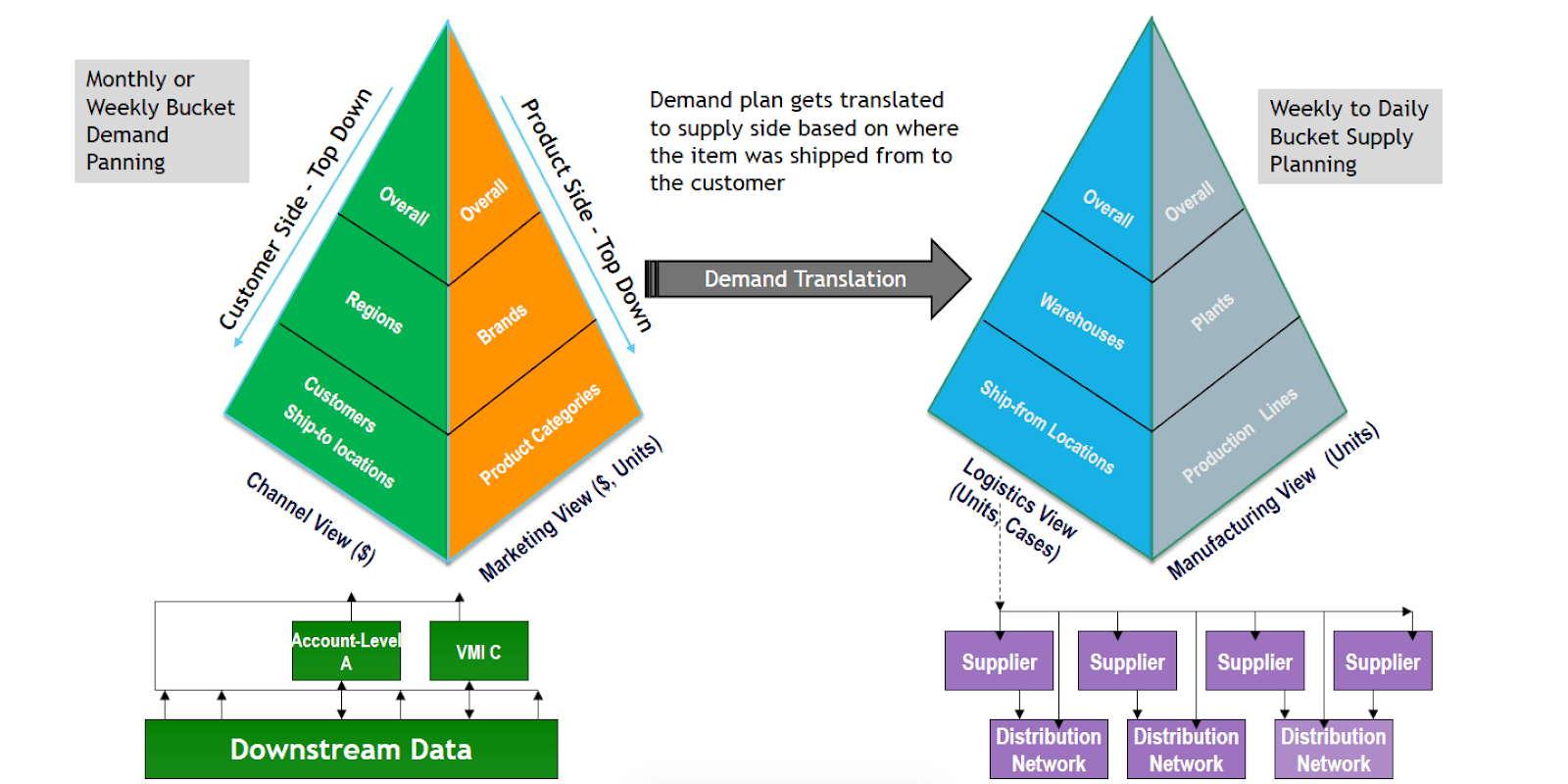

The Fully Integrated S Op Of A Multi Site System In Supply Chain Download Scientific Diagram

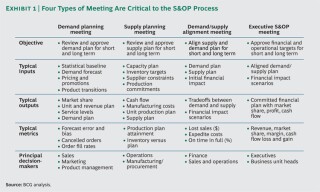

The S&OP discussions makes the decision process much more precise and allows the team to clearly understand the impact of its decisions Step 4 Develop S&OP Plan 4 Develop S&OP Plan 42 Develop Consensus S&OP Plan 41 Review Demand and Supply Scenarios 43 Document Decisions and Issues The S&OP process The process consists of focused review meetings for each discipline and an Executive meeting for decisions The diagram shows a standard model, but the actual number of review meetings are decided within each organisation For example Finance input is part of the preexecutive meeting Map to Profit Center Leadership Drive Alignment to Business Goals The starting place is to build an organizational map by profit center For the greatest success, the S&OP process should report to a profit center manager The number of S&OP processes align to the profit center mapping (The average company has five to six processes, and the

S Op Implementation Roadmap

Dsiop Process Review

Sales and operations planning is an aspect of supply chain planning whose goal is the creation of a unified, consensusbased business plan It draws input from an organization's key functional areas, including sales, marketing, manufacturing, distribution, and finance S&OP is a structured planning process, based on a monthly cycle The objective is to improve the balance between future demands for the market's products and services, the organisation's resources and the supply of materials and services And, of course how the plan will be financed Implementing the S&OP process S&OP Challenges Challenges Senior leadership support & "walk the talk" Achieving process compliance Identifying S&OP Champion or expert to lead implementation Clear definition and acceptance of roles and responsibilities, including defining specific objectives in employee appraisals Establishing S&OP meetings as the business priority

S Op Process

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

The Executive S&OP Meeting is the culminating meeting in the S&OP process that is often preceded by a Portfolio Review, Demand Consensus, Supply Consensus, and PreS&OP meetings It's the S&OP meeting, led by the company's, or business unit's senior executive The Executive S&OP Meeting is where the management team Confirms the summary level operatingProcess symbols are also commonly called flowchart symbols, flowchart shapes or flow diagram symbols These symbols come from the Unified Modeling Language or UML, which is an international standard for drawing process maps These process symbols can be put in the following categories process/operation symbols, branching and control of flow The S&OP process is a broker of informationor to use one of today's common supply chain buzzwords, a 'control tower' A recent Accenture article describes the importance of eliminating the disconnect between sales and supply chain, which is what a proper S&OP operating model seeks to create

What Is S Op How S Op Works Demand Planning Com

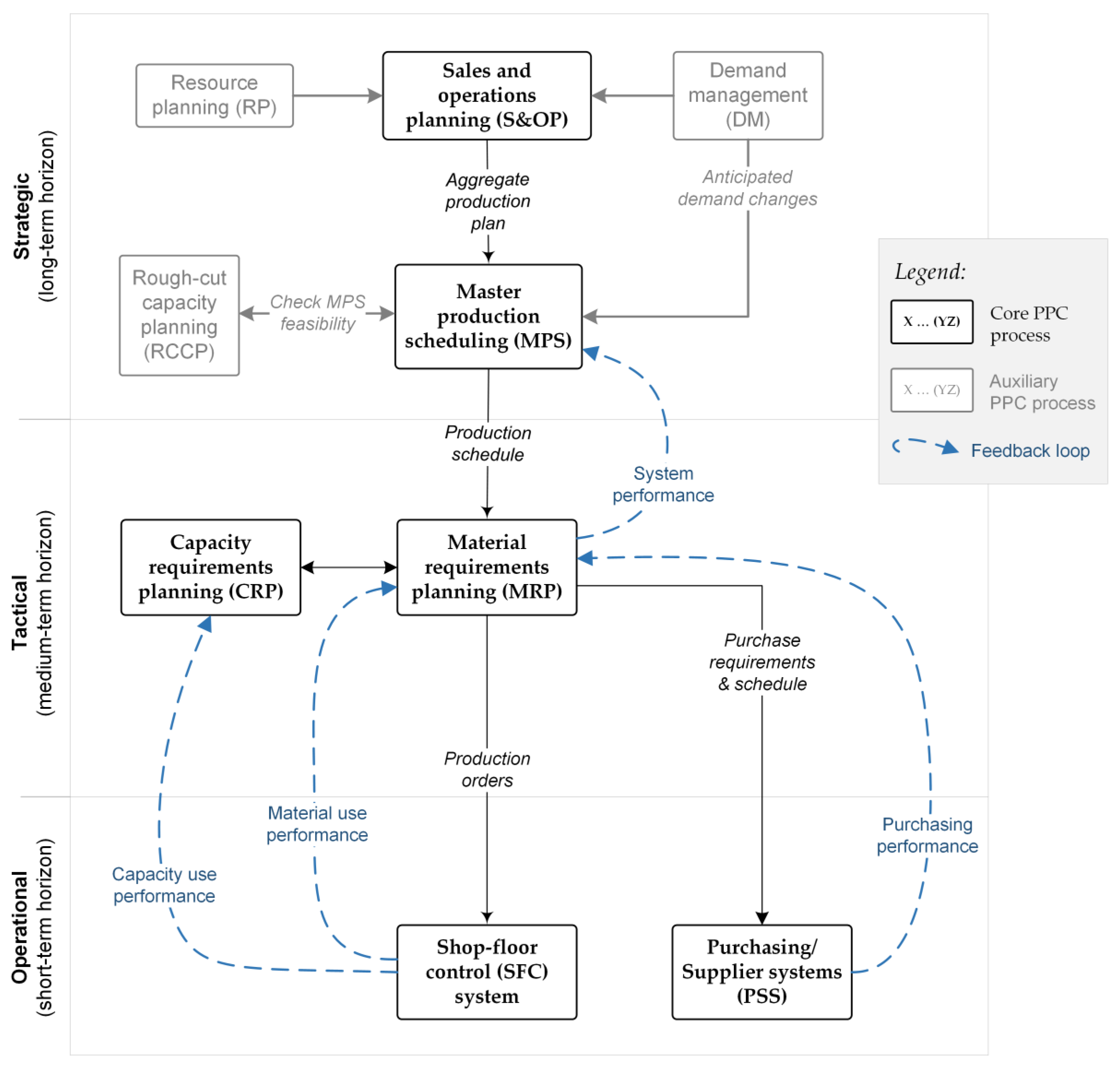

Sustainability Free Full Text Smart Production Planning And Control Concept Use Cases And Sustainability Implications Html

Niels van Hove, consultant with years of experience in supply chain and business planning in Australia, and Supply Chain Movement have put together this checklist to assess the right mindset for an effective S&OP process An S&OP decision making process should result in balanced demand, supply and inventory, periodic visibility in the gapsProcesses and expectations in place to prevent the S&OP process from bogging down, or drifting into unproductive, unfocused efforts BE AN S&OP LEADER Because you are the champion of the team tasked with implementing the S&OP process, you must research what happened previously You have to ask questions to find answersData integration is a oneway highway The S&OP process should be separated from operational planning without losing the link, though The S&OP planning process should always be built on a realistic foundation, as the base line determines the trustworthiness of the S&OP plan

Mindmap For Sales Operations Planning 2 0 Supply Chain Movement

2

Operations planning (S&OP) process is beyond the scope of this paper, this white paper will examine two different approaches to implementing those plans once they are formulated the first is based on rapid replanning in response to exceptions;S&OP process is guided by output from strategic planning and, in turn, drives daily operations This makes S&OP the "linchpin" planning process, connecting strategy to execution Obviously, this is a critical planning process for any business The accuracy of S&OP plans invariably determines how well a company achieves itsS&OP facilitator helps discover why opinions differ while keeping the S&OP process on track S&OP Silos Potential silo conflicts outside of the S&OP process that hinder S&OP performance conflicts of interest, such as one department lowering its costs by offloading expenses onto another department failure to share information, or

Sales And Operations Planning Explorescm

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

S&OP is a monthly management process It provides a link between strategy and execution that engages senior management in a tangible way to make decisions in order to balance company goals and direction with sales and operational capability Getting to a to a level of maturity where this can happen is a tall order A robust S&OP process is the building block upon which to add inventory optimization and create an integrated SI&OP process The company that extends its capability beyond S&OP to SI&OP will reap the benefits of lowered working capital investment, improved service levels and increased sales

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

S Op Five Steps To Get Started Supply Chain Shaman

The Fully Integrated S Op In Supply Chain Planning Context Download Scientific Diagram

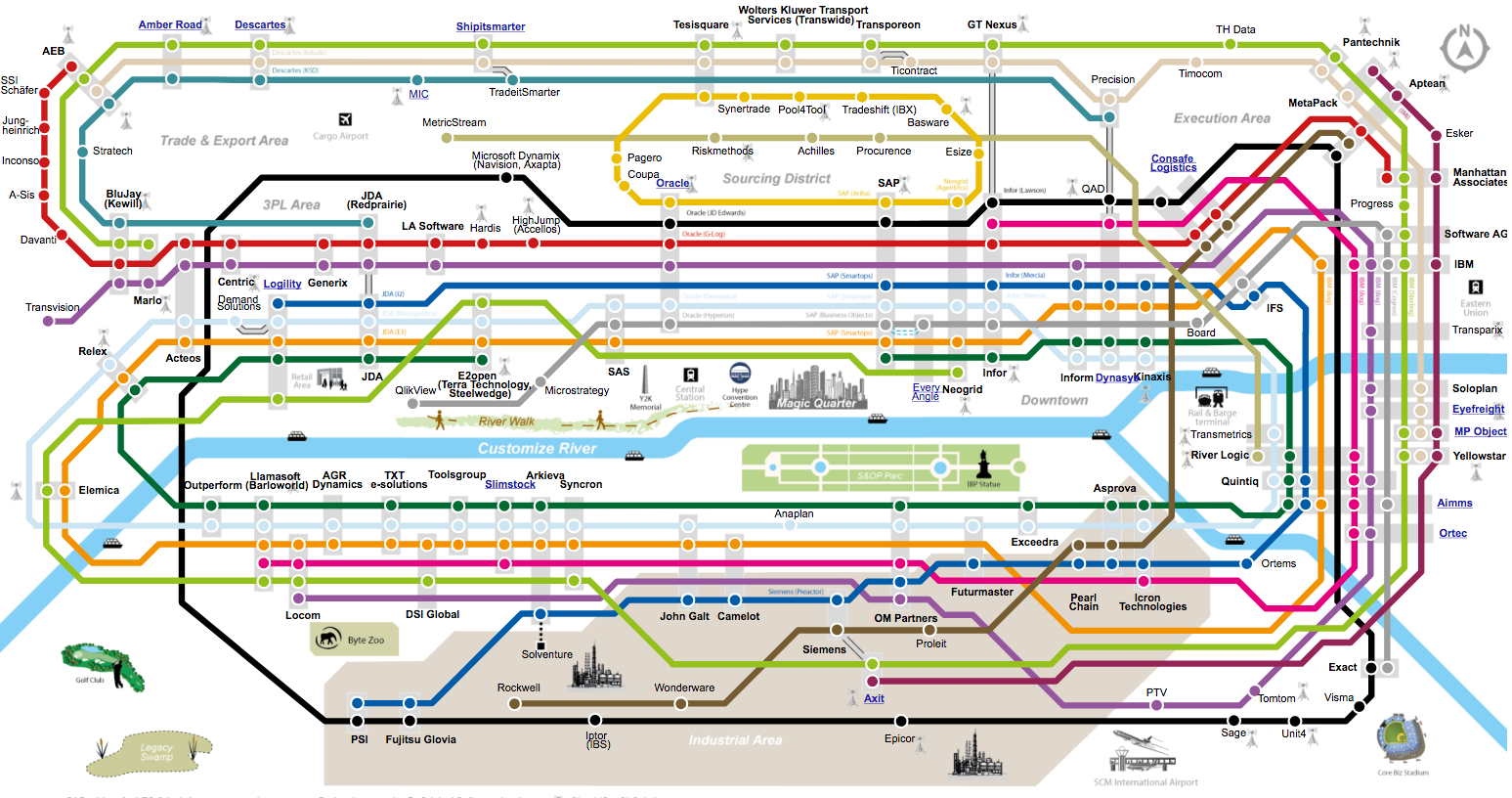

Do Supply Chain Planning Systems Generate Any Value

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Dp Vs S Op Process Flow

A Rudder For Course Correction July 1 09 Cscmp S Supply Chain Quarterly

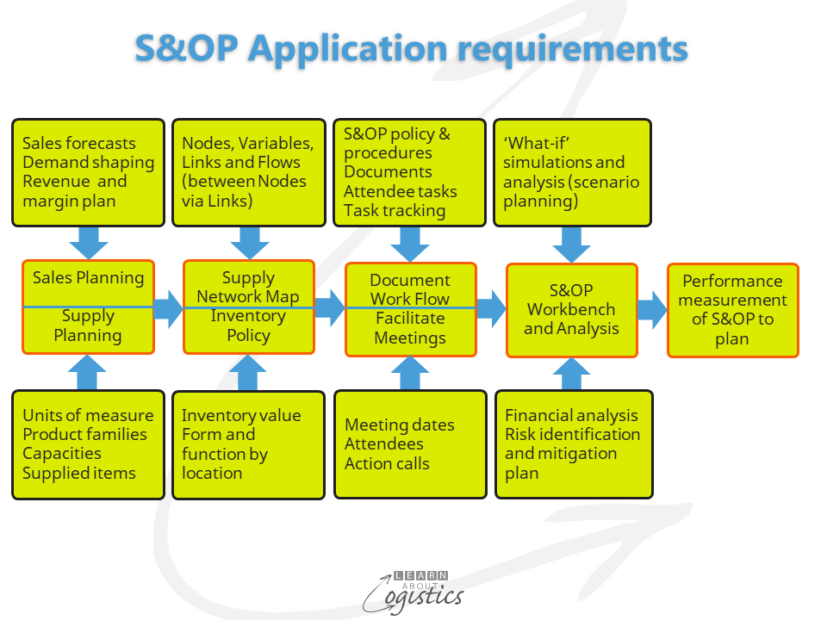

Applications Requirements That Assist S Op Decisions Learn About Logistics

From Chaos To Control July 1 08 Cscmp S Supply Chain Quarterly

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

S Op Made Practical The European Business Review

S Op Process Challenges In Beverage Industry Ppt Video Online Download

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

S Op Sales And Operations Planning And Sco

Sap Sales And Operations Planning Software Product Xsop Pdf Free Download

Mindmap For Sales Operations Planning 2 0 Supply Chain Movement

Framework For Measuring Performance Of The Sales And Operations Planning Process Emerald Insight

1

1

The S Op Framework Source Thome Et Al 12 Download Scientific Diagram

What Is S Op How S Op Works Demand Planning Com

Sales And Operations Planning S Op Monthly Process Conceptdraw Biggerplate

S Op Implementation Roadmap

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

Supply Chain Graphic Of The Week The S Op Process

Sales Operations Planning Consulting Supply Velocity

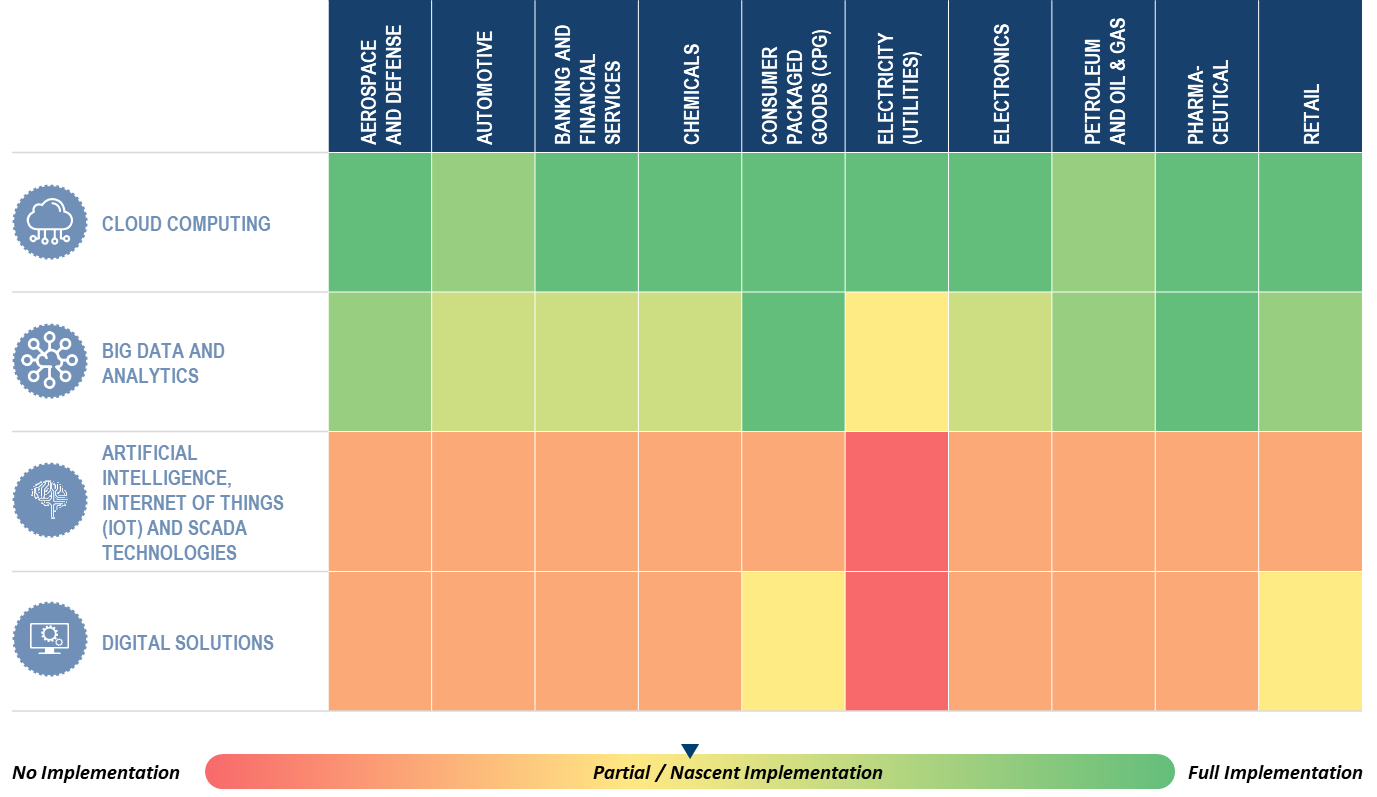

How These 6 Technologies Can Advance Your Sales Operations Planning Apqc

Getting To Grips With Sales And Operational Planning Bloor Research

S Op 360

2

Monthly S Op Process Sales And Operations Planning Wikipedia Sales And Operations Planning Best Apps For Teachers Apps For Teachers

Sales Operations Planning S Op And Sales Operations Execution S Oe Engineering Usa

S Op A Vision For The Future The Expert Interview Series 1 Supply Chain Trend

Involving Execution Managers With Sales And Operations Planning Supply Chain 24 7

S Op Five Steps To Get Started Supply Chain Shaman

2

Framework For Measuring Performance Of The Sales And Operations Planning Process Emerald Insight

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Integrating The S Op Process Go With The Flow Online Sales Guide Tips

What Is S Op How S Op Works Demand Planning Com

My Business Ideas Notebook June 13

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

Five Ways To Upgrade Your Business Planning Process With Advanced Analytics 18 07 24 Supplychainbrain

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

S Op Implementation Roadmap

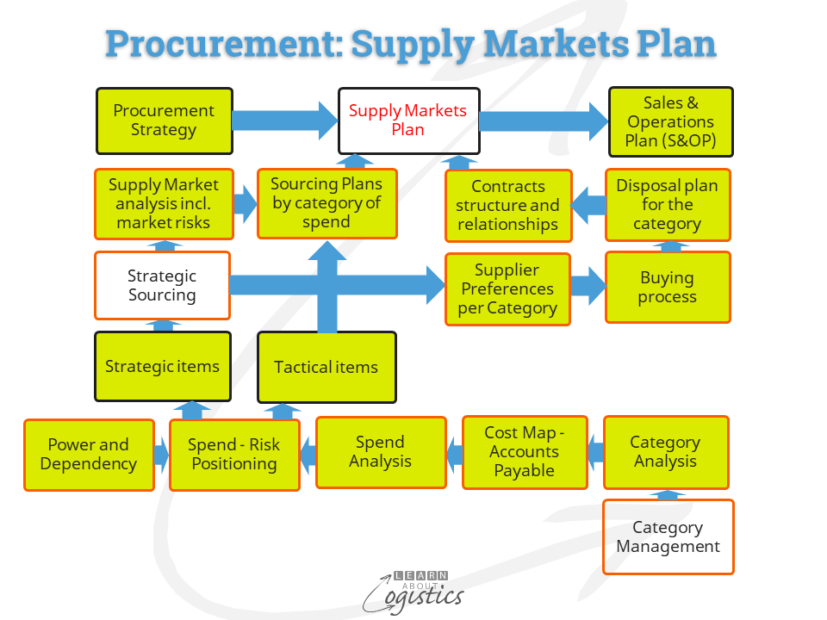

Supply Markets Plan Is A Supply Chain Input To The S Op Learn About Logistics

Sales Operations Planning Omnics

23 S Op Ideas Sales And Operations Planning Supply Chain How To Plan

Self Assessment L Nexview Consulting S Op Consulting

Mindmap For S Op And Ibp Supply Chain Movement

2

Mindmap For S Op And Ibp Supply Chain Movement

The Client Journey Leadership Through Integration Dm Integration

Oracle Demantra Sales And Operations Planning User Guide

Mindmap Sales Operations Planning S Op Supply Chain Movement

S Op Heuristics Flow Chart Download Scientific Diagram

Supply Planning Processes Options Analytics Oh My Plex Demandcaster

S Op Five Steps To Get Started Supply Chain Shaman

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

1

Aimms Featured In It Subway Map Of European Supply Chain Software Providers Aimms

Utilizing A Roadmap For A Successful S Op Implementation Avata

S Op Heuristics Flow Chart Download Scientific Diagram

Solution Framework Of S Op In The Supply Chain Download Scientific Diagram

S Op Process

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Generalized Scor Implementation

S Op Made Good The Importance Of Investing In People Reuters Events Supply Chain Logistics Business Intelligence

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Sales And Operations Planning

A Comprehensive Overview Of Sales And Operations Planning S Op

Sales And Operations Planning S Op 101 Smartsheet

Road Map Of Integrated Business Planning For Supply Chain Part Ii The 5 Ps Of S Op Maturity My Supply Chain Group

Enterra Insights Nine Technologies Transforming The Supply Chain Part 2

Sales Operations Planning Presentation 60 Slide Powerpoint Flevy

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

S Op Implementation Roadmap

The Effect Of Sales And Operations Planning S Op On Supply Chain S Total Performance A Case Study In An Iranian Dairy Company Sciencedirect

1

Sales And Operations Planning

Food Production Processing Operations Transformations All Revolve Around Process First A Case Study In Modern Process Mapping

2

0 件のコメント:

コメントを投稿